Translate:

APPLICATIONS

Since 1954, Chemax TRACIT™ heat transfer cement has been used in industrial heat tracing and temperature maintenance systems where efficient conductive heat transfer is critical. These heat transfer compounds are applied to externally heated process piping, valves, tanks, and vessels to improve thermal contact and enhance system performance.

TRACIT™ heat transfer cement is installed over steam tracing, electric heat tracing, hot oil systems, and other fluid heat tracing installations prior to insulation. By filling surface irregularities and eliminating insulating air gaps, the compound forms a highly conductive interface between the heat source and the process surface, significantly improving heat transfer efficiency compared to bare convection tracing.

In many applications, a single TRACIT™ heat tracing compound installation can maintain pipe temperature where multiple bare tracers would otherwise be required, reducing energy consumption and overall system complexity.

Industrial applications include:

- Pipe freeze protection systems

- Process temperature maintenance

- Industrial heat tracing systems (steam or electric)

- Tank heating using clamp-on (plate-type) coils

- Heat exchangers and heating jackets

- Externally heated or cooled vessels

Chemax Manufacturing Corporation remains a family-owned and operated business, and proudly manufactures all of its products in the United States.

GALLERY

Before and After Cement Application

HEAT TRACING

Industrial heat tracing systems are used to maintain process temperatures and prevent freezing during periods of low or no flow. Steam, electric, and fluid heat tracing systems are widely used across industrial facilities; however, system performance depends heavily on the quality of thermal contact between the tracer and the pipe.

In bare (convection) heat tracing installations, tracer contact with the pipe is intermittent. Much of the heat transfer path occurs through air within the insulation cavity. Because air is a poor conductor, this results in reduced heat transfer efficiency, temperature variability, and increased energy demand.

Common limitations of bare heat tracing include:

- Inconsistent thermal contact

- Performance shifts due to thermal expansion

- Seasonal ambient temperature swings

- Difficulty maintaining elevated pipe temperatures

- Increased steam or power consumption

MAXIMIZING HEAT TRANSFER

Chemax TRACIT™ heat transfer cement creates a direct conductive path between the tracer and the pipe wall. By eliminating insulating air gaps, heat is transferred efficiently from the tracer to the pipe surface, enabling faster heat-up times and higher achievable pipe temperatures.

Typical overall heat transfer coefficients (“U” factors) for bare steam tracers range from 1–5 BTU/hr·sq ft·°F. When heat transfer cement is applied, values commonly increase into the 20–40 BTU/hr·sq ft·°F range.

Conductive Heat Flow

By establishing a continuous conductive interface, thermal resistance at the tracer-to-pipe boundary is significantly reduced. Heat spreads more uniformly through the pipe wall, increasing the effective heat transfer area and improving temperature stability.

A tracer installed with heat transfer cement can effectively heat through a broader circumferential section of pipe compared to bare tracing alone.

Easy Trowel-On Compounds

Chemax TRACIT-300 hardening heat transfer cement is designed for use on steam, electric, and fluid heat tracing systems applied to process piping. The material cures to a durable, high-strength conductive bond within approximately 24 hours and has a maximum continuous service temperature of 750°F (400°C).

For higher-temperature applications, TRACIT-600A is recommended, with a maximum service temperature of 1250°F (675°C).

These compounds provide long-term thermal performance in demanding industrial environments.

Chemax CC Installation Channels

Chemax CC CHANNELS reduce installation time while providing mechanical protection and improved weather resistance for traced piping systems. Available in galvanized or stainless steel. Sold in convenient 4-ft sections.

1/2" x .020" Type 304 stainless steel banding and crimp seals are also available.

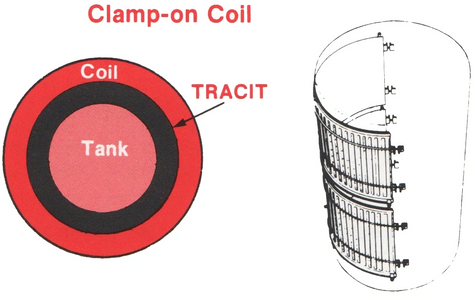

CLAMP-ON COILS

Non-Hardening Heat Transfer Compounds

Chemax non-hardening heat transfer mastics are designed for use with externally mounted plate coils (clamp-on panels) installed on tanks and vessels.

By filling surface irregularities and eliminating air voids between the coil and tank wall, these mastics create a continuous conductive interface that significantly improves heat transfer efficiency for both heating and cooling applications.

Non-hardening TRACIT-1100 is recommended for heating coils, while TRACIT-1000 is suited for cooling applications.

Eliminate Air Voids

TRACIT™ non-hardening mastics maximize conductive heat flow from coil to tank by displacing insulating air gaps. These waterproof compounds also act as a corrosion barrier at the coil-to-tank interface.

Easy Installation & Removal

TRACIT-1100 remains soft and pliable for easy trowel application and removal. No premixing is required, and the material offers indefinite shelf life when stored in sealed containers under normal conditions.

TRACIT-1100 DEMO VIDEO

© 2026 CHEMAX MANUFACTURING CORPORATION

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.